Because waiting until something breaks is never part of the plan.

In this line of work, you know one thing for sure: when a bearing fails, it never happens at a “convenient” time. Production slows down, machines go offline, and suddenly you’re scrambling to find the part, the crew, and the time to fix it.

Most bearing failures don’t come out of nowhere — the signs are usually there. If your team knows what to look for, you can catch problems early and avoid the cost and chaos of unexpected downtime.

Here are five signs your bearings might be on their way out — and how to stay ahead of the problem.

1. Strange Noises or Extra Vibration

If your equipment starts making noises it didn’t used to — squeaking, grinding, or just vibrating more than usual — that’s often your first warning. Bearings don’t just fail silently.

What to do:

Don’t ignore it. Get someone to check it out right away. Vibration analysis or even a simple hands-on inspection can save you from bigger problems down the line.

2. Things Are Running Hot

Bearings will warm up under load, but if a housing feels hot to the touch or hotter than usual, it’s a red flag. It could be an issue with lubrication, overloading, or misalignment.

What to do:

Shut the equipment down and check it before it gets worse. Look for dried grease, discoloration, or anything out of the ordinary. Keep a log — if it’s heating up regularly, something needs to change.

3. The Grease Looks Off

You can learn a lot by looking at your lubricant. If it’s gritty, dark, or you see metal flakes, your bearing is breaking down on the inside — even if everything still looks fine on the outside.

What to do:

Clean it out and inspect the bearing. If metal’s showing up in your grease, don’t wait — replace it. It’s cheaper to swap a bearing now than to fix the damage it’ll cause later.

4. Alignment is Off (Even a Little)

Bearings don’t like being out of line. Misalignment puts uneven stress on everything, leading to premature failure, even if the part itself is high quality.

What to do:

Use proper alignment tools and make sure your team isn’t rushing installs. One fast, sloppy fit can cost you a full shutdown later. If alignment keeps slipping, the root cause may be in your foundation or load design.

5. The Machine Just Feels Off

You know how your equipment normally runs. If things feel sluggish, if motors are straining, or if output’s not where it should be — a bearing could be the cause.

What to do:

Trust your gut. If performance drops, check the bearings before blaming other systems. A small drag inside a worn bearing can throw off an entire process.

When You Need Bearings Fast, We’re Here

At Tork Products, we’ve helped hundreds of teams avoid downtime by getting them the right bearings at the right time — without the runaround. Whether you know exactly what you need or you’re not sure what failed, we’re ready to help.

Need a replacement or just some advice? Call us anytime — we’re available 24/7, because machines don’t wait for business hours to break.

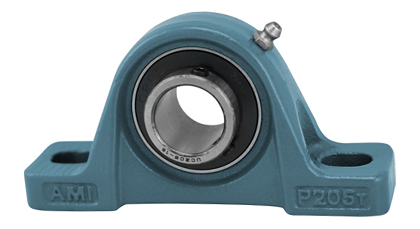

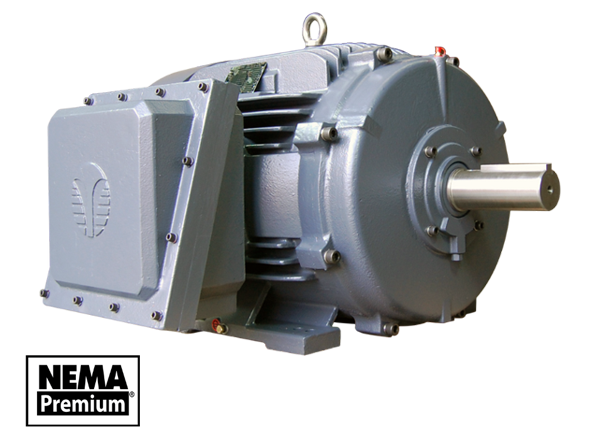

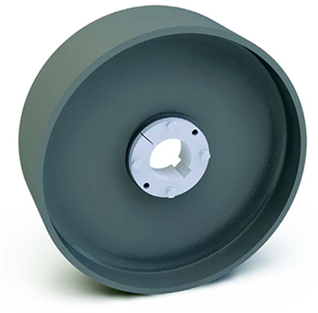

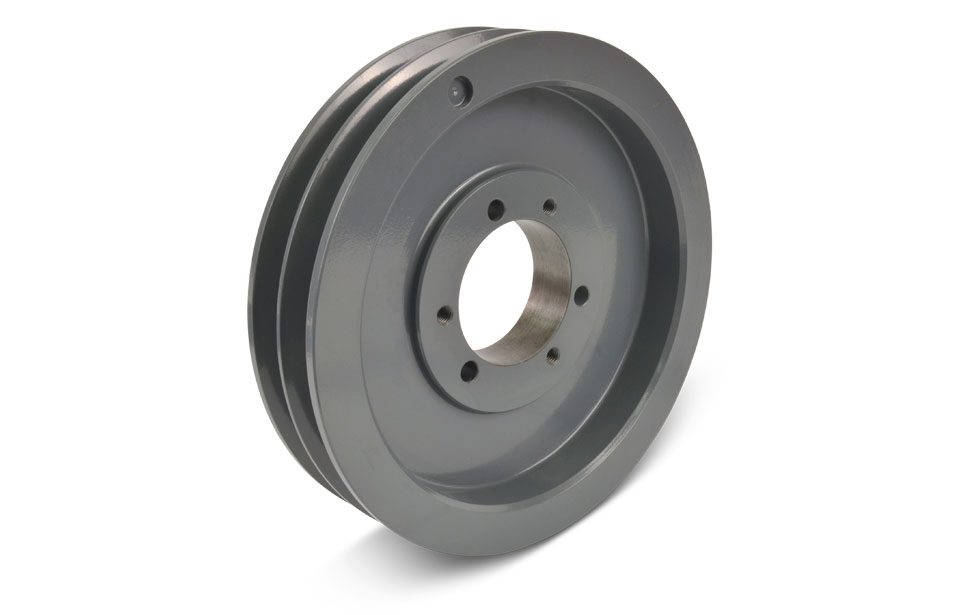

Our Lineup